A distributor is a type of intermediary entity in the supply chain that purchases products, often in bulk, from manufacturers and sells them to retailers or directly to end customers. Distributors play a crucial role in ensuring that products reach their intended markets efficiently and effectively. Here are some key points about distributors:

-

Intermediary Function: Distributors act as middlemen between manufacturers and retailers or end consumers. They help manufacturers reach a wider customer base without having to establish their own sales and distribution networks.

-

Bulk Purchases: Distributors typically purchase products in large quantities from manufacturers at wholesale prices, enabling them to benefit from volume discounts and economies of scale.

-

Storage and Warehousing: Distributors often maintain warehouses or distribution centers where they store inventory. This allows them to fulfill orders quickly and efficiently, especially for products with high demand.

-

Logistics and Transportation: Distributors are responsible for managing the logistics of moving products from manufacturers to retailers or end customers. This includes transportation, inventory management, and order fulfillment.

-

Market Access: Distributors have established networks and relationships with retailers, making it easier for manufacturers to reach new markets or expand their distribution reach.

-

Value-Added Services: Some distributors offer value-added services such as technical support, after-sales service, marketing assistance, and product customization to meet the specific needs of customers.

-

Risk Management: Distributors help manufacturers mitigate risks by taking on the responsibility of storing and selling products. This can help manufacturers focus on production while distributors handle distribution and sales.

-

Industry-Specific: Distributors exist in various industries, including electronics, automotive, pharmaceuticals, and consumer goods, among others. Each industry may have specialized distributors who cater to specific market segments.

Overall, distributors play a critical role in the supply chain by bridging the gap between manufacturers and end customers, facilitating the efficient distribution of goods and helping businesses reach their target markets effectively.

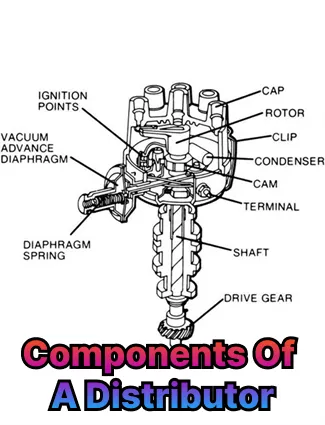

List of Components Of A Distributor In A Vehicle

In a traditional automotive internal combustion engine, the distributor is a crucial component responsible for routing high-voltage electricity from the ignition coil to the spark plugs in the correct firing order. However, with advancements in automotive technology, many modern vehicles now use distributorless ignition systems (DIS) or coil-on-plug systems that have eliminated the need for a traditional distributor.

For vehicles equipped with a traditional distributor, here are the main components found within a typical distributor assembly:

-

Housing: The housing is the outer casing of the distributor that contains and protects the internal components.

-

Cap and Rotor:

- Distributor Cap: The distributor cap sits on top of the distributor housing and directs the high-voltage electricity from the ignition coil to the rotor and then to each spark plug wire in the correct firing order.

- Rotor: The rotor is located beneath the distributor cap and rotates, making contact with the distributor cap electrodes to transfer the high-voltage current to the spark plug wires.

-

Shaft and Gear: The distributor shaft connects the distributor with the camshaft, and there's usually a gear at the base of the distributor shaft that meshes with the camshaft gear to drive the distributor.

-

Ignition Module:

- Points and Condenser (in older systems): In older distributor systems, the points and condenser were used to control the flow of electricity from the coil to the spark plugs.

- Ignition Control Module (ICM): In more modern distributor systems, an electronic ignition control module controls the timing of spark generation.

-

Vacuum Advance (optional): Some distributors may contain a vacuum advance mechanism that adjusts the ignition timing based on engine load and operating conditions.

-

Distributor Cap Contacts: These contacts within the distributor cap are where the spark plug wires connect to facilitate the transfer of electricity to the spark plugs.

-

Spark Plug Wires: These are the insulated wires that carry the high-voltage spark from the distributor cap to the corresponding spark plugs in each cylinder.

-

Centrifugal Advance: This mechanism also adjusts the ignition timing based on engine RPM, preventing engine knocking at high speeds.

-

Condenser: In older distributors, a condenser is used to reduce electrical interference caused by the opening and closing of the contact points.

-

Ignition Coil: The ignition coil is a key component that generates the high-voltage spark required for ignition. It stores electrical energy and discharges it when the distributor's contact points open or the electronic sensors trigger.

Remember, with the prevalence of modern electronic ignition systems like coil-on-plug and distributorless systems in many vehicles today, the traditional distributor components are becoming less common in newer vehicles.

How Many Types of Distributors

In the business context, particularly within the realm of sales and distribution, there are various types of distributors that companies may engage with based on their distribution strategies and needs. Here are some common types of distributors:

-

Wholesalers:

- Wholesalers purchase goods in bulk from manufacturers and sell them to retailers or other businesses. They typically do not deal directly with end consumers.

-

Retailers:

- Retailers purchase goods from wholesalers or directly from manufacturers and sell them to end consumers through physical stores, online platforms, or other sales channels.

-

Agents/Brokers:

- Agents or brokers act as intermediaries between manufacturers and buyers, earning a commission for facilitating sales without taking ownership of the goods.

-

Distributors:

- Distributors take ownership of products from manufacturers and sell them to retailers, other distributors, or end customers. They play a key role in expanding the reach of manufacturers' products.

-

Value-Added Distributors:

- Value-added distributors provide additional services such as technical support, training, marketing assistance, and customization of products to meet specific customer requirements.

-

Specialty Distributors:

- Specialty distributors focus on specific industries, product categories, or market segments, providing specialized distribution services tailored to the needs of those sectors.

-

Franchise Distributors:

- Franchise distributors operate within a franchise system, representing a specific brand or company in distributing its products to customers.

-

Exclusive Distributors:

- Exclusive distributors are granted exclusive rights to distribute a manufacturer's products in a specific region or market segment, limiting competition and maximizing focus on sales.

-

Industrial Distributors:

- Industrial distributors cater primarily to businesses and industries, supplying them with industrial products, equipment, and components necessary for their operations.

-

Multiple Channel Distributors:

- Multiple channel distributors utilize various distribution channels, including online sales, brick-and-mortar stores, and partnerships with other distributors to reach diverse customer segments.

These are just some common types of distributors found in the business landscape, each serving a unique role in the distribution chain based on the products they handle, the markets they serve, and the services they provide.

How Does A Distributor Work

In an internal combustion engine, particularly in older vehicles, a distributor is a critical component of the ignition system that distributes high-voltage electricity to the spark plugs in the correct firing order. Here's a general overview of how a distributor works in a traditional ignition system:

-

Ignition Coil: The process begins with the ignition coil, which generates high-voltage electricity. The ignition coil is connected to the battery and generates a high voltage that is needed to create the spark at the spark plugs.

-

Rotor and Distributor Cap:

- The distributor consists of a rotor located inside a distributor cap. The rotor is attached to a camshaft gear and rotates as the engine spins.

- The distributor cap sits on top of the distributor housing and contains electrodes that correspond to each cylinder in the engine.

-

Firing Order:

- The firing order is the sequence in which the spark plugs in the engine's cylinders receive the high-voltage current to ignite the air-fuel mixture at the correct time during the engine's cycle.

-

Camshaft Connection:

- The distributor is connected to the engine's camshaft, which is synchronized with the rotation of the crankshaft. As the engine turns, the distributor rotates at half the speed of the crankshaft.

-

Points and Condenser (in older systems):

- In older ignition systems, the distributor includes points and a condenser. The points open and close to interrupt the flow of current from the ignition coil to the spark plugs in sync with the engine's cylinders' firing order.

-

Distributor Cap Contacts:

- Inside the distributor cap, there are contacts that correspond to each spark plug wire. As the rotor spins inside the cap, it makes contact with these electrodes, sending high-voltage electricity to the correct spark plug wire at the right time.

-

Timing Adjustment:

- The distributor also includes a mechanical or vacuum advance mechanism that adjusts the ignition timing based on engine speed, load, and other factors to optimize engine performance.

-

Spark Plug Ignition:

- When the rotor makes contact with the correct electrode in the distributor cap, high-voltage electricity is transferred through the spark plug wire to the corresponding spark plug, creating a spark to ignite the air-fuel mixture in the engine cylinder.

Modern vehicles increasingly use distributorless ignition systems (DIS) or coil-on-plug systems, where electronic control units (ECUs) manage the ignition timing and eliminate the need for a traditional distributor. These systems offer improved reliability, efficiency, and precise control of ignition timing compared to older distributor systems.

How to Maintain Distributor

Maintaining a distributor is crucial for ensuring the proper functioning of the ignition system in older vehicles that still use this component. Here are some tips on how to maintain a distributor effectively:

-

Regular Inspection:

- Periodically inspect the distributor components, including the cap, rotor, contacts, and wiring, for signs of wear, corrosion, or damage.

-

Check and Clean Components:

- Clean the distributor cap and rotor to remove any dirt, debris, or carbon buildup that may interfere with the transfer of electricity.

- Inspect and clean the contacts inside the cap to ensure good electrical conductivity.

-

Replace Worn Components:

- Replace the distributor cap, rotor, and spark plug wires if they show signs of wear, cracking, or corrosion. Worn components can lead to misfires and engine performance issues.

-

Check and Adjust Timing:

- Verify and adjust the ignition timing as needed to ensure optimal engine performance. Use a timing light to set the timing correctly based on the manufacturer's specifications.

-

Inspect Vacuum Advance Mechanism:

- If your distributor has a vacuum advance mechanism, check the vacuum lines for leaks or damage. Ensure the vacuum advance is functioning correctly and adjust it as needed.

-

Replace Points and Condenser (if applicable):

- In older distributor systems with points and condenser, replace the points and condenser periodically to maintain reliable ignition performance.

-

Inspect Wiring and Connections:

- Check the wiring connections to the distributor for tightness and signs of corrosion. Repair or replace any damaged wires to prevent electrical issues.

-

Use Dielectric Grease:

- Apply dielectric grease to the inside of the distributor cap to prevent moisture buildup and corrosion, which can affect the electrical connections.

-

Maintain Proper Grounding:

- Ensure that the distributor is properly grounded to the engine block to prevent electrical issues and interference.

-

Professional Inspection:

- If you are unsure about maintaining the distributor yourself, consider taking your vehicle to a qualified mechanic for a thorough inspection and maintenance of the distributor.

Regular maintenance of the distributor can help prevent ignition-related problems, ensure smooth engine operation, and extend the lifespan of the ignition system components.

Signs of A Distributor Problem You Should Notice

Recognizing signs of a distributor problem early can help prevent more significant issues with your vehicle's ignition system. Here are some common signs that indicate potential distributor problems:

-

Engine Misfires:

- One of the most noticeable signs of a distributor issue is engine misfires, which can manifest as rough idling, hesitation, or a lack of power during acceleration.

-

Difficult Starting:

- If you experience difficulty starting your vehicle, especially in damp or humid conditions, it could indicate a problem with the distributor components.

-

Stalling:

- Sudden stalling of the engine, particularly at idle or low speeds, can be a sign of distributor problems affecting the ignition system.

-

Backfiring:

- Backfiring, which involves loud noises from the exhaust or intake during engine operation, can be caused by improper spark timing due to distributor issues.

-

Poor Fuel Economy:

- A failing distributor can lead to inefficient combustion, resulting in decreased fuel efficiency and increased fuel consumption.

-

Engine Performance Issues:

- Reduced engine performance, such as a lack of power, sluggish acceleration, or a decrease in overall engine responsiveness, can be attributed to distributor problems affecting spark timing.

-

Visible Wear or Damage:

- Inspect the distributor components for visible signs of wear, corrosion, or damage, including cracked distributor caps, worn rotors, or corroded contacts inside the distributor cap.

-

Unusual Smells:

- Unusual smells, such as the smell of burning rubber or electrical burning, could indicate electrical issues within the distributor that need attention.

-

Check Engine Light:

- If the Check Engine Light illuminates on the dashboard, it can indicate various problems, including issues with the ignition system, which could be related to the distributor.

-

Electrical Issues:

- Electrical problems like intermittent loss of power to the spark plugs or inconsistent spark timing can be signs of distributor malfunctions.

If you notice any of these signs or suspect issues with your distributor or ignition system, it is essential to have the vehicle inspected and diagnosed by a qualified mechanic. Addressing distributor problems promptly can help prevent further damage and ensure the continued reliable operation of your vehicle.