As the demand for high-quality ceramic analogs continues to grow in various industries, finding reliable suppliers is essential for businesses seeking top-notch products.

China, known for its robust manufacturing sector, is home to numerous ceramic analog suppliers that cater to diverse needs. This comprehensive article aims to streamline your search by presenting a curated list of notable ceramic analog suppliers in China. Whether you're involved in electronics, telecommunications, or other industries requiring precision ceramics, this compilation serves as a valuable resource for discovering reputable suppliers and enhancing your sourcing strategies.

Detailed Information about Ceramic Analog

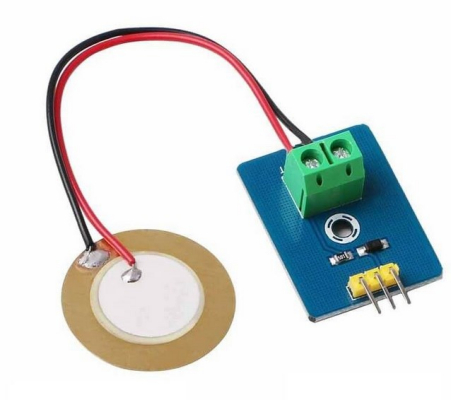

It seems like you might be referring to "ceramic analog" in the context of electronic components, especially in the field of electronics or technology. However, if you are specifically referring to a different term or concept, please provide more context so that I can offer you the most accurate information.

In the realm of electronic components, ceramics are widely used for various applications. Here is some general information about ceramic analog components:

-

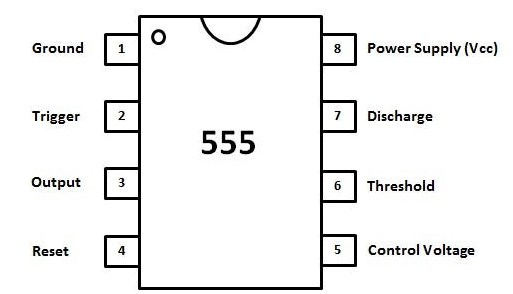

Ceramic Capacitors: Ceramic capacitors are a type of capacitor that uses ceramic materials for the dielectric. These capacitors are widely used due to their stability, reliability, low cost, and compatibility with surface mount technology (SMT). They are commonly used in filtering, decoupling, timing, and tuning applications.

-

Ceramic Resistors: Ceramic resistors are resistors made with a ceramic core coated with a resistive material. They are commonly used in high-temperature applications, where stability and precision are crucial. Ceramic resistors offer advantages such as high power handling capability, high stability, and low inductance.

-

Ceramic Filters: Ceramic filters are electronic components used to filter out unwanted signals or noise in electronic circuits. They are known for their high Q factor, narrow bandwidth, and stable performance over a wide range of temperatures. Ceramic filters are commonly used in communication systems, audio processing, and RF applications.

-

Ceramic Substrates: Ceramic substrates are used as the base material for electronic circuits in various applications. These substrates provide excellent thermal management, high mechanical strength, and good electrical insulation properties. Ceramic substrates are commonly used in power electronics, LED modules, and automotive electronic systems.

-

Ceramic Inductors: Ceramic inductors are inductive components that use ceramic materials as the core. They are used in high-frequency applications where stability and performance are critical. Ceramic inductors offer advantages such as high Q factor, low parasitic capacitance, and excellent temperature stability.

Overall, ceramic analog components offer a range of advantages in electronics, including stability, reliability, high performance, and compatibility with various applications. They play a crucial role in various electronic systems and circuits, contributing to efficient and reliable operation.

Full List of 5 Ceramic Analog Suppliers in China

As of my last update in September 2021, I can't provide real-time or current data. However, I can mention some well-known ceramic components suppliers in China that could potentially offer ceramic analog components:

-

Murata: Murata is a global supplier of electronic components, including ceramic capacitors, inductors, filters, and resonators. They have a significant presence in China and are known for their high-quality ceramic products.

-

TDK Corporation: TDK is another major player in the electronic components industry, offering a wide range of ceramic components such as capacitors, inductors, and filters. They have a strong presence in China and provide high-quality ceramic analog components.

-

Yageo Corporation: Yageo is a leading manufacturer of passive electronic components, including ceramic capacitors and resistors. They have a presence in China and offer a variety of ceramic analog components for different applications.

-

Jingguang (Fujian) Electronic Ceramics Co., Ltd.: Jingguang is a Chinese company specializing in the production of electronic ceramic components, including ceramic capacitors, resonators, and filters. They are a trusted supplier of ceramic analog components in the Chinese market.

-

Fenghua Advanced Technology: Fenghua Advanced Technology is a Chinese company that manufactures a wide range of electronic components, including ceramic capacitors, inductors, and filters. They have a presence in China and supply ceramic analog components to various industries.

Please note that the availability and current status of these suppliers may have changed since my knowledge was last updated in September 2021. It's recommended to verify the information and conduct further research to find the most suitable supplier based on your specific requirements and needs.

How to Find&Verify Ceramic Analog Suppliers in China[Suggestions For You]

Finding and verifying ceramic analog suppliers in China involves several steps to ensure you are dealing with legitimate and reliable companies. Here are some suggestions to help you in the process:

Finding Ceramic Analog Suppliers in China

-

Online Directories: Use reputable online directories such as Alibaba, Global Sources, Made-in-China, and Thomasnet to search for ceramic analog suppliers based in China. These platforms list numerous suppliers and allow you to filter based on your requirements.

-

Trade Shows and Exhibitions: Attend industry trade shows and exhibitions focused on electronics and components held in China. These events provide an opportunity to meet suppliers in person, inspect their products, and establish relationships.

-

Business Networks: Utilize professional networking platforms like LinkedIn to connect with professionals in the electronics industry in China. They may offer recommendations or introductions to reputable suppliers.

-

Industry Associations: Contact industry associations such as the China Electronic Components Association (CECA) for information on trusted ceramic analog suppliers in China.

-

Referrals and Recommendations: Seek recommendations from peers, industry experts, or business contacts who have experience sourcing electronic components from Chinese suppliers.

Verifying Ceramic Analog Suppliers in China

-

Company Background Check: Research the supplier's background, including their history, size, certifications, and reputation in the industry. Look for online reviews and testimonials from other customers.

-

Factory Visit: If possible, consider visiting the supplier's manufacturing facilities in China to assess their production capabilities, quality control processes, and overall operational standards.

-

Certifications and Compliance: Verify that the supplier adheres to relevant quality standards such as ISO certifications and compliance with industry regulations.

-

Sample Testing: Request samples of the ceramic analog components to evaluate their quality, performance, and suitability for your specific requirements.

-

Communication and Transparency: Engage in open communication with the supplier to clarify your expectations, specifications, pricing, lead times, and other terms of the agreement. A reliable supplier should be transparent and responsive to your queries.

-

Payment Terms and Contracts: Review and negotiate clear payment terms and contracts with the supplier to ensure a mutually beneficial and secure business relationship.

-

Third-Party Assessment: Consider using third-party services for supplier assessment and verification to obtain unbiased insights into the supplier's credibility and reliability.

By following these suggestions and conducting thorough research and due diligence, you can identify and verify reputable ceramic analog suppliers in China for your business needs.

Final Verdict

When finalizing your decision on a ceramic analog supplier in China, it is crucial to prioritize trust, quality, and reliability. Here is a summarized final verdict to guide you through the selection process:

-

Thorough Research: Conduct extensive research on potential suppliers through online directories, trade shows, business networks, industry associations, and referrals.

-

Verification Process: Verify the supplier's background, certifications, compliance with standards, and customer feedback to ensure their credibility and reputation.

-

Physical Inspection: Whenever feasible, visit the supplier's manufacturing facilities to assess their production capabilities, quality control procedures, and overall operational standards.

-

Sample Testing: Request samples of the ceramic analog components to assess their quality, performance, and compatibility with your requirements.

-

Transparency and Communication: Ensure clear and open communication with the supplier regarding expectations, specifications, pricing, lead times, and other terms of the agreement.

-

Contracts and Payment Terms: Review and negotiate transparent contracts and secure payment terms to establish a mutually beneficial and secure business relationship.

-

Third-Party Assessment: Consider utilizing third-party assessment services for unbiased insights into the supplier's reliability and trustworthiness.

By following these steps and guidelines, you can make an informed decision and select a reputable ceramic analog supplier in China that meets your business needs and standards. Prioritizing due diligence and quality assurance is key to establishing a successful and sustainable partnership with your chosen supplier.