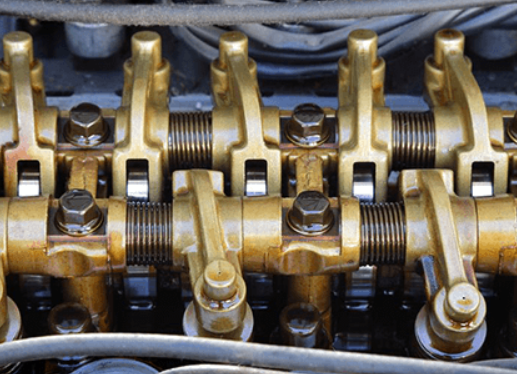

It may have happened on your trip that you heard a knocking sound in your vehicle's engine. While there are varied levels of severity, one thing stays constant: it is a condition that must be addressed immediately by a professional. This can be dangerous because it can cause engine damage if left untreated. In this article, we will take you through the meaning of feedback knock, the causes behind it, and how to troubleshoot this issue effectively.

What is Feedback Knock in an Engine

Feedback knock, also known as knock feedback, refers to a system found in some modern engines that helps monitor and manage engine performance in real-time. Knock, also called detonation, is an undesirable condition that can occur in internal combustion engines where the air-fuel mixture ignites spontaneously and irregularly rather than burning smoothly and evenly. This uncontrolled combustion can lead to various issues, including engine damage.

Here's how the feedback knock system typically works:

-

Knock Detection: Microphones (in some cars) or vibration sensors are used to detect the characteristic sound or vibrations produced when knock occurs in the combustion chamber. Knock sensors are devices that can detect these irregular combustion events.

-

Feedback Loop: When the knock sensor picks up the signature sounds or vibrations of knocking, it sends signals to the engine control unit (ECU) or engine management system.

-

Adjustments: The ECU can make adjustments to the engine's operation in response to knock feedback. This might include retarding the ignition timing, adjusting the air-fuel mixture, or taking other corrective actions to prevent knock from causing damage.

-

Monitoring: The feedback knock system continuously monitors the engine's performance, making real-time adjustments to optimize combustion and prevent knock events.

In performance-tuned engines or turbocharged engines, knock can be more common due to increased cylinder pressures, temperatures, and the potential for detonation. The feedback knock system helps protect the engine by detecting knock early and adjusting engine parameters accordingly to prevent potential damage.

Drivers and technicians can also monitor knock levels through diagnostic tools in some vehicles, allowing them to take corrective actions or adjust tuning parameters to minimize knock events and maintain optimal engine performance and reliability.

Is Feedback Knock Bad

Feedback knock itself is not inherently bad; it's actually a protective feature designed to prevent engine damage. Feedback knock indicates that the engine's knock sensors have detected knocking or detonation occurring in the combustion chamber. Knocking can lead to serious issues like engine knocking noise, reduced engine power, decreased fuel efficiency, and potentially even engine damage if left unchecked.

When the feedback knock system detects knock events, it allows the engine control unit (ECU) to make real-time adjustments to prevent further knocking. These adjustments might include retarding ignition timing, adjusting the air-fuel mixture, or taking other corrective actions to protect the engine.

In a properly functioning engine, feedback knock is a useful tool that helps optimize engine performance and protect the engine from harm. However, persistent or severe feedback knock can indicate underlying issues with the engine, fuel quality, tune, or other factors that need to be addressed to prevent long-term damage.

If you notice frequent or severe feedback knock events, it's important to have your engine checked by a qualified mechanic to diagnose and address the root cause of the knocking to ensure the engine continues to run smoothly and reliably.

What Causes Feedback Knock

Feedback knock, or knock detected by the engine's knock sensors and reported to the engine control unit (ECU), can be caused by various factors. Here are some common reasons for feedback knock in an engine:

-

Low-Grade Fuel: Using fuel with an octane rating lower than what the engine requires can lead to knock. Higher-compression engines or turbocharged engines often require higher octane fuel to prevent knocking.

-

High Engine Load: Under high load conditions, such as when accelerating hard or climbing steep grades, the engine may be more prone to knock due to increased cylinder pressures and temperatures.

-

High Ambient Temperatures: Hot ambient temperatures can increase the likelihood of knock, especially in engines that are already running close to their thermal limits.

-

Carbon Build-Up: Carbon deposits on the pistons, cylinder walls, or spark plugs can create hot spots that lead to knock.

-

Incorrect Ignition Timing: Improperly set ignition timing can cause the air-fuel mixture to ignite at the wrong time, leading to knock.

-

Faulty Knock Sensor: A malfunctioning knock sensor may not accurately detect knock events, leading to incorrect feedback to the ECU.

-

Lean Air-Fuel Mixture: Running too lean (too much air, too little fuel) can cause the air-fuel mixture to ignite prematurely, resulting in knock.

-

Mechanical Issues: Engine mechanical problems, such as excessive carbon buildup, damaged pistons, or worn bearings, can lead to knock.

-

Aftermarket Modifications: Performance modifications like altered intake/exhaust systems or engine tuning that are not properly calibrated can sometimes lead to knock.

-

Driving Conditions: Driving at consistently high speeds, towing heavy loads, or aggressive driving styles can increase the likelihood of knock.

It's important to address the underlying cause of feedback knock to prevent potential engine damage. Regular maintenance, using the correct fuel grade, keeping the engine properly tuned, and addressing issues promptly can help minimize the occurrence of knock events in the engine.

How to Troubleshoot Feedback Knock

Troubleshooting feedback knock involves identifying the root cause of the knocking detected by the engine's knock sensors. Here are some steps you can take to troubleshoot feedback knock in an engine:

-

Check Fuel Quality: Ensure that you are using the correct fuel grade with the recommended octane rating for your engine. Using lower-grade fuel than required can lead to knock.

-

Inspect Spark Plugs: Check the condition and gap of the spark plugs. Worn or incorrectly gapped spark plugs can contribute to knocking. Replace spark plugs if necessary.

-

Scan for Trouble Codes: Use an OBD-II scanner to check for any trouble codes related to knock sensor performance or engine timing issues.

-

Check for Vacuum Leaks: Inspect the vacuum lines for any leaks, as a vacuum leak can cause a lean air-fuel mixture, which may lead to knock.

-

Examine Ignition Timing: Verify that the ignition timing is set correctly. Incorrect ignition timing can contribute to knock. Consult the manufacturer's specifications for the recommended timing.

-

Inspect the Knock Sensor: Check the knock sensor and associated wiring for any damage or loose connections. A faulty knock sensor can provide inaccurate feedback to the ECU.

-

Clean Carbon Deposits: Remove carbon buildup from the pistons, cylinder walls, and spark plugs. Carbon deposits can create hot spots that lead to knock.

-

Monitor Driving Habits: Be mindful of driving conditions and habits that can lead to knock, such as high engine load, aggressive driving, or consistently high speeds.

-

Address Engine Mechanical Issues: If you suspect mechanical issues, such as worn components or damaged parts, have the engine inspected by a qualified mechanic.

-

Professional Diagnosis: If you are unable to identify the cause of feedback knock or if the issue persists despite your troubleshooting efforts, consider taking your vehicle to a mechanic or dealership for a more comprehensive diagnosis.

By systematically checking these potential causes of feedback knock, you can identify and address the underlying issue to help prevent knock events and ensure the optimal performance and longevity of your engine.